BCL BRAND SITE

公式Instagram

The Saborino brand was developed by the BCL Girls’ Development Lab.The sheet mask series that features in the brand range was developed through careful in-house research, carried out in response to some ultimate lazy skincare demands: “mornings are so busy for women!”, “facial cleansing in the morning is so much hassle!”, “I just want to cut down the time I spend on skincare in the morning”.

More than carefully selected 30 ingredients are blended over three hours in a large, sealed tank. The resulting fluid is, one might say, “food for the skin”. It is blended in accordance with strict hygiene management processes.

A sample is taken from each tank of blended fluid and subjected to quality testing. We check not only for the presence of microbes and bacteria, but also whether the fluid is formulated correctly. In addition to machine testing, these checks involve careful testing by human eye, looking for even the slightest discrepancies in color and odor. This is a crucial process in ensuring product quality.

Our masks are made by cutting a lightweight yet strong non-woven textile into a face shape using our bespoke mask formation cutter. The non-woven textile we use is distinct for its stretch. This enables the mask to fit freely to the face, and also prevents slippage.

It also features a slightly larger cut mouth, to enable “on-the-go skincare”, for example while you’re eating or brushing your teeth.

Our sheet masks are packaged in a unique trifold system that makes them hassle-free and hygienic to use every single day. The system also enables a super simple application technique, keeping to a minimum those parts touched by hands when removing the mask from its packaging – meaning the mask can be pulled out from its packaging smoothly and applied straight to the face in a single movement. These tri-folded masks are packaged in layers in transparent packaging.

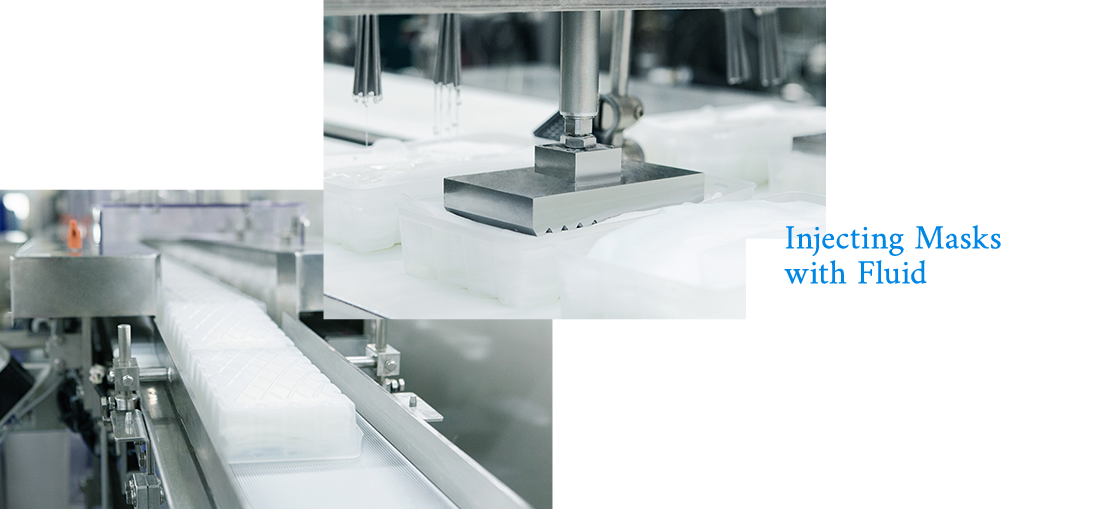

We’re confident that each Saborino mask is loaded with skincare fluid, right down to the last mask in the pack. One of the innovative ways we achieve this is by loading the masks with content fluid three times. By repeating the pressing and fluid injection stages, we ensure that the fluid penetrates each mask effectively and that every mask is soaked with skincare fluid.

We add a transparent seal above the layered, folded masks, then wrap them in film, complete with a plastic cap. The seal protects the masks from evaporation and from fluid spilling out of the film packaging. The small dispenser cap ensures the makes are kept well sealed, guaranteeing that each mask is loaded with product, right down to the last one.

After machine testing the product weight, we also conduct careful checks by human eye. We examine each and every wrapped package, looking for even the tiniest defects and leaks.

Products which have passed through our multi-stage testing process are then shipped nationwide. We use the very latest in power-assisted suit technology to ensure both smooth product transportation and a safe working environment.